Technical Aspects of the Full Scale APT MLS10

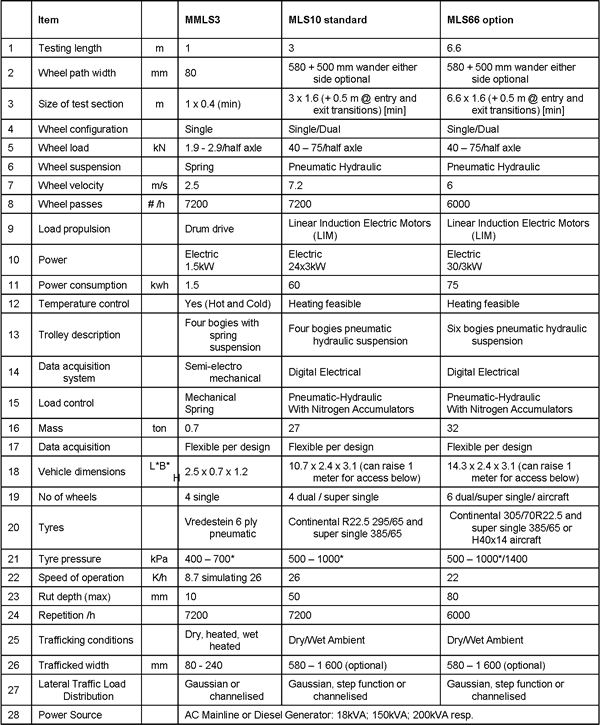

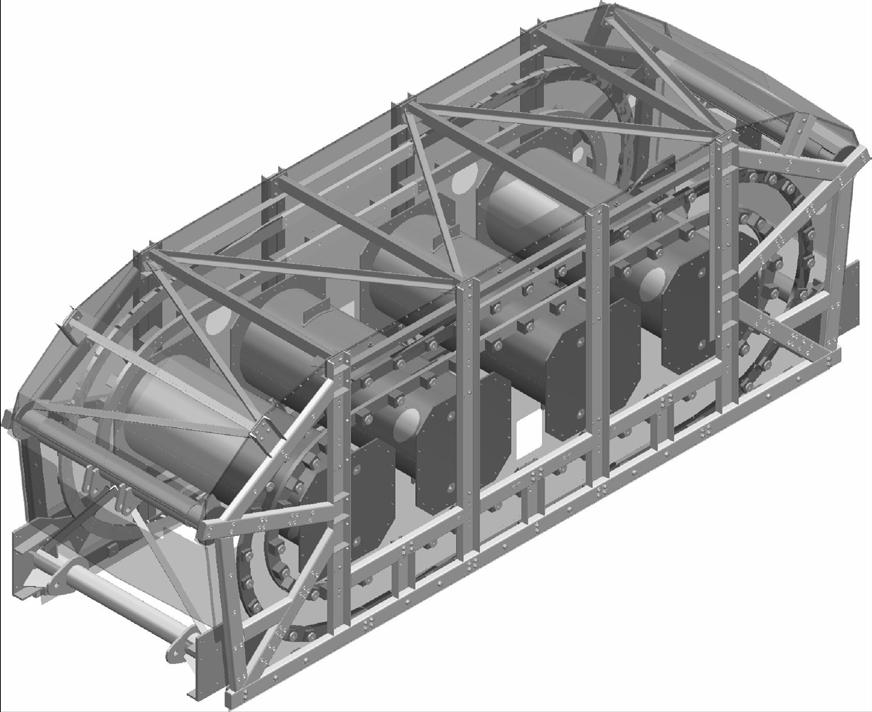

The MLS10 is based on the third scale load simulator, MMLS3 produced by MLS Test Systems Pty Ltd in Stellenbosch, South Africa . The operating principle of the two devices is very much the same. The machine structure is a space frame approximately 10m long, 3m high and 2.4m wide. The MLS10 has four wheel bogies, each fitted with two 295/65 R22.5 (940mm diameter) or similar tyres. The maximum load on each set of dual wheels is 6 tons (60 kN) at maximum speed. The system is designed to enable the bogies to travel at up to a maximum speed of 7.2 m/s (26 km/hr), when 7 200 axle loads are being applied per hour. The maximumload can be increased when the speed is reduced. Load control is semi-automatic with the load applied hydraulically.

Each bogie has 12 sets of guide wheels. Each wheel set consists of two wheels, the inner one being a 250mm diameter flanged steel wheel to apply the load. The outer one is also a 250mm diameter steel wheel linking the bogie chain.

Loading MLS10 in Stellenbosch for transit to Mozambique

Provision has been made to get access to the pavement under the machine for the purpose of testing, measurements and, diagnostic inspection. There are primarily two options that can be used. Firstly by either pulling the machine off the test section on its transport wheels; or by jacking it up high enough to be able to work underneath it. Long distance transport of the machine is by low bed trailer by road or rail.

Environmental conditions during testing are important. Trafficking can be done at ambient conditions or with the pavement at temperatures of -10C to 70C as per the APT performance specification. However, the conditioning of the pavement has to be done by auxiliary systems. The surrounding environmental conditions during testing have a profound effect on the efficiency and effectiveness of the auxiliary environmental systems. Different methods have been developed to cater for the various scenarios with different MLS testing devices.

The composition of a MLS test system should preferably comprise the following:

-MLS10 with profilometer and a data collection system

-A seismic testing tool such as the PSPA

-A MMLS3 with

- a temperature chamber

- a water heating unit

- a heated air unit

- a core test bed

A system such as the above could be delivered within six months after receipt of a firm order. Depending on the research requirements a unit also capable of freezing the pavement could be included. It is worth noting that full-scale APT users are now utilizing the MMLS3 for prescreening tests and exploratory investigations.

Comparison of MMLS3 and MLS10 APT Machine Parameters