Contact us

Division of Polymer Science

Department of Chemistry

and Polymer Science

University of Stellenbosch

Private Bag X1

7602 MATIELAND

South Africa

Telephone:

+27 (21) 808 3172

Where to find us

GPS Coordinates:

S 33° 55' 58" E 18° 51' 59"

Equipment available at Polymer Science

Last revision: 31 March, 2022

Chromatography Electrospinning Physical characterisation Spectroscopy Thermal analysis Other

PL GPC 220

High temperature chromatograph

Room: 2035

Contact person: Dr Helen Pfukwa

Responsible person: Dr Anthony Ndiripo

Gel permeation chromatography/size exclusion chromatography (GPC/SEC) is the technique of choice for rapid and reliable characterization of polymer molar mass and molar mass distribution (MMD).

The PL-GPC 220 is an extremely flexible chromatography system with full automation and equipped with refractive index (RI) detection, used to analyse mostly polyolefins at higher temperatures (150°C). Samples are prepared by using the PL-SP 260 sample preparation system, designed for the dissolution and filtration of samples prior to HT GPC analysis. The unit combines controlled heating across a temperature range of 30 - 260°C, with gentle agitation for the proper dissolution of semi crystalline polyolefins.

LC-Transform 303

Room: 2035

Contact person: Dr Helen Pfukwa

Responsible person: Dr Anthony Ndiripo

The LC-Transform is a solvent evaporative interface used to collect the SEC/HPLC separated fractions. The collected fraction on the rotating Germanium disc are further analysed by general FTIR spectroscopy.

This is highly useful for the determination of the chemical structure/physical properties across the molar mass distribution (in combination with HT SEC) or across the chemical composition distribution (in combination with HT HPLC). This application includes the measurement of short chain branching, crystallinity, composition distribution, etc.

SGIC

Solvent gradient interaction chromatograph

Room: 1013

Contact person: Dr Helen Pfukwa

Responsible person: Dr Anthony Ndiripo

Solvent gradient interaction chromatograph (SGIC) is a new chromatographic system for high temperature two-dimensional liquid chromatography (HT 2D-LC) analysis, constructed by Polymer Char (Valencia, Spain), comprising of an autosampler, two separate ovens, 2D switching valves and two pumps equipped with vacuum degassers (Agilent, Waldbronn, Germany).

An evaporative light scattering detector (ELSD), PL-ELS 1000, is used as a detector. HT 2D–LC enables the generation of two dimensional characterization data (chemical composition distribution vs molar mass distribution) for all polyolefins over a wider composition range.

DMF SEC

Dimethylformamide size exclusion chromatograph

Room: 2036

Contact person: Dr Helen Pfukwa

Responsible person: Dr CM Smit, L Kellerman, RD Cunningham

Size exclusion chromatography (SEC) is a liquid chromatography method for analyzing macromolecules on the basis of molar mass (Mn), and moler mass disparity (Đ). Our system runs on a dimethyl acetamide (DMAc) solvent system, and it is suitable for the analysis of polar polymers e.g. poly(N-vinylpyrrolidone) (PVP), certain poly(acrylates) and poly(urethanes).

Our instrument setup consists of a Shimadzu LC-10AD pump, a Waters 717Plus autosampler, a column system fitted with a 50 x 8 mm guard column in series with three 300 x 8 mm, 10 μm particle size GRAM columns (2 x 3000 Å and 100 Å) obtained from PSS, a Waters 2487 dual wavelength UV detector and a Waters 410 differential refractive index (DRI) detector all in series. The system is calibrated against narrow molecular weight poly(methylmethacrylate) (PMMA) standards.

HPLC

High performance liquid chromatograph

Room: 1012

Contact person: Dr Helen Pfukwa

Responsible person: Dr Ndumiso Sibanda

High performance liquid chromatography (HPLC) is an analytical liquid chromatographic tool for analysing macromolecules on the basis of their adsorption properties with the column. The Agilent 1260 infinity LC is fitted with a quaternary pump which allows a wide selection of HPLC solvents to be used.

This system is compatible with most commercially available columns hence it is applicable to almost all known polymers both polar and non-polar. In addition to the quaternary pump, the instrument comprises an Agilent 1200 autosampler, a 25 cm x 4.6 mm, 5 µm C18-column, a diode array detector (UV detector) and an evaporative light scattering detector (ELSD) all connected in series.

HPLC

High performance liquid chromatograph

Room: 2034

Room: 2034

Contact person: Dr Helen Pfukwa

Responsible person: Dr Ndumiso Sibanda

The above three HPLC instruments are equipped with a degasser, quaternary pump, auto sampler, thermostatted column oven, isocratic pump, a single ultraviolet detector as well as an evaporative light scattering detector (ELSD). The HPLC instruments are used for the separation of polymers i.e. homopolymers and copolymers and other non-volatile compunds according to their interaction with the column packing. Since polymers are heterogeneous with respect to functionality (end groups), chemical composition (type of repeating units), molecular architecture (i.e. linear or branched) and molar mass (chain length). Careful selection of the type of column and solvent system and column temperature allows for the separation of polymers with regard to the fore mentioned properties.

The quaternary pump allows separation of polymers by using a solvent gradient while the thermostatted column allows for separation of polymers using a temperature gradient. The combination of solvent system and column determine whether you will perform normal phase HPLC or reversed phase HPLC. The above mentioned instruments are able to perform two-dimensional chromatographic experiments which allow separation according to the two preselected properties i.e. in the first dimension you can separate polymers with regard to chemical composition and the second dimension can separate polymers with regard to molar mass by choosing the appropriate columns and solvent systems.

GPC (Breeze - THF)

Gel permeation chromatograph

Room: 2036

Contact person: Dr Helen Pfukwa

Responsible person: Joshua Johani/Chelsea Williams

The above mentioned instrument is equipped with a degasser, isocratic pump, an auto sampler, column housing compartment, which is not temperature controlled, a refractive index detector and a dual wavelength ultraviolet detector.

This instrument is used to separate polymers with regard to molar mass. There is no interaction between the polymer and the column packing, polymers are separated depending on their size relative to the pore size of the column. Molecules smaller than the pore size enter the pore and large molecules are excluded, this leads to the larger molecules being eluted first out of the column and the smaller molecules eluted last. This type of separation is known as size exclusion chromatography or gel permeation chromatography. This GPC instrument uses tetrahydrofuran as an eluent. It is calibrated with respect to polystyrene so the molar masses of the analysed compounds are relative to polystyrene.

FFF

Field flow fractionation can be defined as an elution based chromatography-like method in which the separation is carried out in a single liquid phase. In FFF an external perpendicular field is applied which works in direct concert with the flow pattern in the channel to achieve separation and characterization of polymers, powders, emulsions, environment colloids and many natural materials.

Thermal field flow fractionation (ThFFF)

Room: 2027

Contact person: Dr Helen Pfukwa

Responsible person:

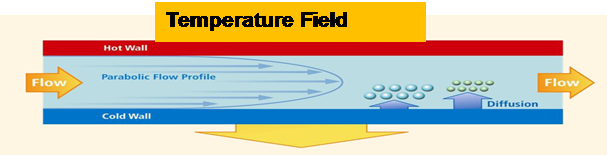

In ThFFF, the "field" is a temperature gradient imposed across the channel by flat heat-conducting bars positioned on each side of the channel to generate solute migration near one wall (usually the cold one) by thermal diffusion (DT). ThFFF separations are governed by two transport mechanisms acting in opposition DT and D. D (diffusion coefficient) describes the movement of mass against a concentration gradient and it is dependent on the molecular weight. DT is a basic transport coefficient describing the movement of matter under an applied temperature gradient and it is generally independent of the molecular weight, but dependent on chemical composition.

To achieve the temperature gradient, the hot wall is kept at an elevated temperature (Th) through the use of software controlled heating rods and the cold wall is kept cool at lower temperature (Tc) using a recirculating chiller.

In ThFFF seperation is based on both molecular weight and chemical composition.

Asymmetrical flow field flow fractionation (AF4)

Room: 2027

Contact person: Dr Helen Pfukwa

Responsible person: Chelsea Williams

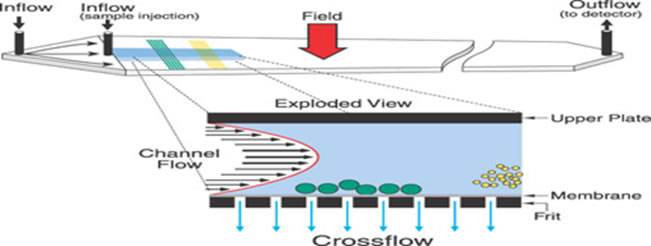

AF4 utilises one permeable bottom wall (accumulation wall) and one solid upper wall. The accumulation wall comprises of a ceramic frit covered by an ultrafiltration membrane, which determines the cut-off molecular weight of samples to be analysed in the channel. Single channel inlet flow is split into the axial (main) flow and the cross flow which is the field.

AF4 is more common due to its high efficiency and simpler construction. Different sized particles are separated by the velocity gradient inside the channel, according to their diffusion coefficient (D), thus separation is dependent on molecular weight and size.

Trapezoidal channel geometry is used in AF4 so as to maintain the axial flow velocity.

CRYSTAF

Crystallisation analysis fractionation

Room: 1007

Responsible person: Dr Anthony Ndiripo

CRYSTAF is a fully automated instrument intended for the fast measurement of the chemical composition distribution (CCD) in polyolefins. The process occurs during a single controlled temperature ramp, where the polymer solution is cooled down and thus crystallizes out of solution. The concentration is monitored by means of an infrared detector.

The instrument has five crystallization vessels and can thus analyse five polymer samples simultaneously. The user puts the dry polymer samples in the vessels after which the virtual instrumentation software controls the process. At the end of the analysis, approximately 8 to 10 hours, the instrument automatically cleans the vessels and lines. The results are obtained directly from the software.

SCALLS equipment

Solution crystallisation by laser light scattering

Room:

Responsible person: Prof AJ van Reenen

This allows for the measurement of the solution crystallization of polyolefins by laser light scattering, and while it performs much the same type of measurement as Crystaf®, the technique is more sensitive, and much faster. In addition it allows for fundamental, basic research which in turn creates opportunities for post-graduate programs and papers to be published.

PALS

Positron annihilation lifetime spectrometer

Room: 1004

Responsible person: Prof PE Mallon

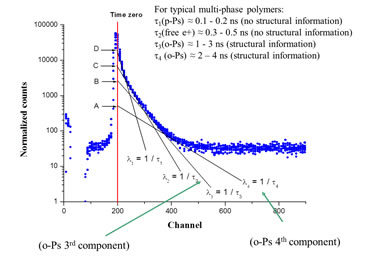

PALS provides direct measurement of the free volume properties of polymer materials. This is achieved by measuring the positron annihilation lifetime spectrum of positrons in the polymer. In the case of the PALS in polymers, the lifetime spectrum can typically be resolved in three or four components depending on the complexity of the morphology of the polymer. The third and fourth components (the longest lived components) correspond to the annihilation of the ortho-positronium (o-Ps) which is localised within the free volume of the polymer.

These lifetimes can be used to determine the size and number of the free volume “holes” in the polymer. The o-Ps atom is the ideal probe of the free volume in polymer materials since its very short lifetime (about 2 – 5 ns) in the polymer free volume holes means that it will spend its entire lifetime in a single hole despite the dynamic nature of the free volume in polymer materials and its size is in the same order of magnitude (although smaller) than the typical free volume hole.

Typical positron annihilation lifetime spectrum showing four components.

The Instrument capabilities: The current PALS system has a specially developed sample holder system which allows for measurements to be done from room temperature up to 200°C, without significantly reducing the count rate for the acquisition of the lifetime spectrum.

Microhardness tester

Room: 1003

Contact person: Dr Helen Pfukwa

Responsible person: Dr Divann Robertson

The hardness tester has the ability to indent polymer samples with loads as low as 50 mN, and at variable indentation rates and dwell times thus allows teh user to do direct comparison of mechanical properties (like hardness values) with molecular composition variations. This is fundamental to the understanding of structure/property relationships.

Brookfield viscometer

Room: 1010

Responsible person: Lauren Ball

The Brookfield DV-II+Pro Viscometer measures fluid viscosity of dispersions, emulsions and latex samples at given shear rates. Viscosity is a measure of a fluid’s resistance to flow. The principal of operation of the DV-II+Pro is to drive a spindle immersed in the test fluid through a calibrated spring.

The viscous drag of the fluid against the spindle is measured by the spring deflection. Spring deflection is measured with a rotary transducer. The measurement range of a DV-II+Pro (in centipoise or milliPascal seconds) is determined by the rotational speed of the spindle, the size and shape of the spindle, the container the spindle is rotating in, and the full scale torque of the calibrated spring.

Optimelt melting point apparatus

Room: 1010

Responsible person: Lauren Ball

Determining a sample’s melting point serves as a rapid, indicative analysis of its identity and purity. It is often encountered in many quality control regimes and in the pharmaceutical industry since the results are easily reproducible and no standards are required if the sample’s melting point is known. Our melting point apparatus is an Optimelt MPA100 automated melting point system.

This device is equipped with an automated operating system, PID-controlled temperature control with a Pt RTD sensor, fan-assisted cool-down, digital video data acquisition, stand-alone LCD display and operation as well as USB integration to a computer terminal and a printer output. The built-in algorithm uses digital image processing to determine the sample’s phase transitions which has shown improvement over optical absorption or reflection techniques. Temperature range: Ambient (+10°C for best reproducibility) – 400°C.

Reactor system

Room: 1007

Responsible person: Prof AJ van Reenen

Purchased from Autoclave Engineers, incorporating Sentinel®control system (Watchtower® software) and integrated mass flow controller. This allows for good control and monitoring during olefin polymerization reactions (pressure, gas flow, temperature).

Impact tester

Room: 1007

Responsible person: Dr AHA Roediger

The instrument uses a weighted pendulum to measure the energy needed to break a rectangular sample. The impact strength is calculated as the energy needed to break the sample, divided by the cross-sectional area of the sample. Tests done on this instrument (Ceast) include tensile impact tests, where the impact force is directed parallel to the lengfth of the sample, and IZOD impact tests, where the impact force is directed perpendicular to the lenght of the sample. Notched impact strength can also be determined. We also have facilities for falling weight impact tests.

Impact tester

Room: 1020

Responsible person: Dr AHA Roediger

MTS instrument capable of IZOD and Charpy impacts, notched as well as unnotched.

Abrasion tester (Sutherland rub tester)

Room: 2024

Responsible person: Dr AHA Roediger

The PIRA abrasion tester (also known as scuff tester) is used in design and graphics packaging applications, in measuring the abrasion resistance of substrates such as paper, varnishes and foils. The scuff tester provides a comparative test for these measurements, and works on the principle of mechanically scuffing the test substrate with a specified abrasive substrate under a specified weight.

MFI

Melt flow index plastometer

Room: 2024

Responsible person: Dr AHA Roediger

The Ceast MFI measures the flowability of thermoplastic polymers and is used often for polyolefins. The MFI gives an indication of the flow properties of the melt, thus indicating processing qualities of the polymer. The MFI can also give an indication of flow rate of polymers, application fields of polymers (injection moulding, extrusion blow moulding) as well as grade consistance of polymers.

Tensile tester

Room: 2024

Responsible person: Dr AHA Roediger

The Instron tensile tester measures basic mechanical properties of polymer samples. The instrument uses a load cell to stretch a sample at a set strain rate, while recording the force as a function of strain. This enables the following calculations: tensile strength, yield point, tensile modulus and other mechanical property data, tenacity of fibers, etc.

Fluorescence/luminescence spectrophotometer

Room: 1014

Contact person: Dr Helen Pfukwa

Responsible person: Lauren Ball

The Perkin Elmer LS 50B instrument has a wide range of automated accessories which makes it ideal for bio-analytical applications. It is equipped with monochromators on both excitation and emission sides and is capable of both emission and excitation of 200 – 800 nm scans. The instrument runs on Fl Winlab version 4 for data processing.

UV-VIS spectroscopy

Ultraviolet-visible spectroscopy

Room: 1014

Contact person: Dr Helen Pfukwa

Responsible person: Dr Chandré Smit

UV spectroscopy measures the wavelength (180 – 1100 nm) and degree of light absorbed by a compound. It is primarily used to measure the absorbance of conjugated and aromatic compounds. Temperature control (Peltier controlled cell holders: -10 – 105°C) is also available to observe the absorbance spectra as a function of temperature.

FTIR

Fourier transform infrared spectrophotometer

Room: 1009

<Contact person: Dr Helen Pfukwa

Responsible person:

The Nicolet iS10 FTIR equipment is regarded as essential with regard to characterization of materials, and in particular with regard to following degradation reactions of polymers. As part of fundamental research teh FTIR spectrophotometer is a way of simply identifying subtle morphological changes. ATR and PAS detectors are already available for addition to the FTIR spectrometer.

This instrument consists of an ATR (attenuated total reflectance) unit for fast surface analysis of samples as well as a transmission–FTIR unit. It is a complete infrared spectroscopy system for routine analytical needs. It delivers the highest confidence in the verification and identification of materials and is designed for maximum assurance in its ability to sample and solve challenging problems with a minimal investment in time.

FTIR Microscope

Fourier transform infrared microscope

Room: 1009

Contact person: Dr Helen Pfukwa

Responsible person:

The Nicolet iN10 IR Microscope is an integrated infrared microsampling system that provides the highest available IR sensitivity with no need for external FT-IR spectrometer. The integrated design delivers the highest possible throughput in infrared microscopy, which allows the analysis of samples as small as 50 microns with no need for LN2, while providing exceptional sensitivity down to 10 micron, when using the cooled detector. All Nicolet iN10 infrared beam path mirrors are gold coated, with the exception of the objective and the condenser, for maximum performance in any sampling mode. We upgraded the microscope with a motorized stage for mapping experiments in transmission, reflection and ATR sampling modes. The pixel size in imaging mode can be 50, 25, 6.25 and 2 microns (ATR). The imaging optical zoom provides 6.25 micron high spatial resolution in transmission and reflection, and better than 2 micron spatial resolution in ATR mode.

The Nicolet iN10 infrared microscope is also designed to provide the highest confidence in the results, offering valuable features for the day-to-day user like:

~ Simultaneous viewing and collection - ensures consistency between data and image

~ True-view aperture - ensures consistency between measured area and data

~ ValPro option - ensures system performance qualification, in any sampling mode

The Nicolet iN10 is fully automated and software controlled, with the exception of the stage, which can be manual or motorized. OMNIC Picta™ software interface provide a truly intuitive interface and it is specifically designed to allow non-skilled personnel to measure samples reliably, consistently and with minimum learning requirements.

FTIR with PAS

Fourier transform infrared spectrophotometer with photo-acoustic cell

Room: 2024

Responsible person: Dr AHA Roediger

A sample is put in the path of an infrared beam. Certain characteristic infrared frequencies are absorbed and the resulting transmittance spectrum is characteristic of the compound analysed.

In the photo-acoustic spectroscopy technique, modulated radiation is absorbed by the sample and causes a periodic temperature fluctuation within the optical absoption depth and periodic heat transfer to an ambient gas occurs. The photo-acoustic spectroscopy signal results from the periodic pressure fluctuations in this gas that are associated with the temperature modulation produced by the heat transfer from the sample.

DSC

Differential scanning calorimeter

Room: 1009

Contact person: Dr Helen Pfukwa

The instrument is used for standard DSC analysis. This can be used to determine crystallization, melt and glass transition temperatures of the polymers. Modulated DSC, which specifically helps resolve Tg transitions that are not visible during normal DSC runs, can be used. Isothermal crystallization experiments can also be done.

TREF

Temperature rising elution fractionation

Room: 1007

Responsible person: Dr Megan Matthews

The instrument, which was constructed in-house, allows for the fractionation of semi-crystalline polymers by means of crystallizability. The process involves slow cooling of a suitable polymer/solvent combination at around1°C/hour from 130°C to ambient temperature, and the subsequent elution of the fractionated material by stepwise temperature increase.

Density gradient column

Room: 1007

Responsible person:

Density is one of the most widely used parameters to characterize the degree of crystallinity in semi-crystalline samples. We have designed and custom built a density gradient column specifically to have a linear gradient in the range expected for polyolefin samples.

This has proved to be a valuable addition to our analysis capabilities and has provided an additional means of characterizing fractions obtained from preparative TREF. It has also proved to be extremely useful to correlate the density results with free volume measurements using PALS.

DMA

Dynamic mechanical analyser

Room: 2024

Responsible person: Dr AHA Roediger

This technique allows dynamic mechanical analysis of thermosets or other materials. Various additions to the system allow analysis of samples in the form of fibers and films, or very soft samples as well as penetration and expansion analysis. The low conductivity measurement package allows low conductivity measurements to be made through the use of a remote integrated circuit sensor.

TGA

Thermogravimetric analyser 7

Room: 2024

Responsible person: Dr AHA Roediger

This Perkin Elmer TGA measures the mass of a substance as a function of temperature, as the sample is subjected to a controlled temperature programme and a controlled atmosphere.

Single needle, “Nanospider” and ball electrospinning apparatus

Image: Single needle electrospinning

Room: 1006

Image: "Nanospider" electrospinning

Room: 2037

Responsible person: Prof PE Mallon

Electrospinning is a simple process that allows for the processing of polymer materials into polymer nanofibres. This is achieved by applying a high voltage to a polymer solution. The polymer solution is contained in a reservoir (syringe) and is fed to the steel needle tip (spinneret) by a pump. A high voltage is then applied to the tip of the needle and a grounded collector plate is placed a certain distance from the needle.

The potential difference between the spinneret and the collector plate induces an electrostatic charge gradient. The charged droplet of polymer solution at the needle tip then deforms into what is called a Taylor cone. When the forces built over the droplet overcome the surface tension of the solution, the polymer solution forms a jet that stretches and whips from the charged needle tip to the grounded collector plate. The solvent evaporates during this stretching of the polymer jet and ultrafine polymer fibres are collected on the earthed collector. The bending of the fibre jet as it accelerates towards the target collector results in the reduction of the fibre diameter, every time this whipping action occurs.

DDI water

Distilled-deionised water

Room: 1037

Responsible person: Lauren Ball

The PureLab produces type II, distilled-deionised water, perfect for a wide range of applications such as reagent make-up, buffer preparation and general purpose HPLC. It delivers seven litres of water an hour with high purity (15 MΩ-cm). Constant water recirculation maintains consistent water purity. The instrument comprises a pre-treatment cartridge, reverse osmosis cartridge, ion-exchange module and a photo-oxidation module to remove bacteria.

Ultra Turrax IKA T25

Room: 1037

Responsible person: Lauren Ball

Dispersions are mixtures of at least two substances that: don’t dissolve in each other, marginally dissolve in each other, or don’t chemically react with each other. During a dispersing process one substance (dispersed phase) is distributed throughout another substance (continuous phase). The term coined for such a mixture is an emulsion or suspension.

Dispersion with an ULTRA TURRAX is based on the rotor-stator principle. In this process the rotor is moved with high circumferential speed. The rotation produces suction that pulls the medium into the rotor and then pushes it to the outside with the help from the stator’s teeth. The products are either emulsions (liquid droplets in a continuous phase) or dispersions (solid particles smoothly distributed throughout the continuous phase). Dispersing with an ULTRA TURRAX is considered to be a high shear process for the dispersion of liquid droplets and solid particles in a continuous phase. This process is a simple and effective alternative to sonication to achieve emulsions and dispersions in a relatively short time scale compared to sonication.

Picoclave reactor

Room: 1037

Responsible person: Lauren Ball

The reactor allows reactions to be conducted at high temperatures (~180°C) and pressure (8 bar < x < 10 bar) while applying a high degree of agitation (3000 rpm). It features an oil bath with temperature control and a double walled glass reactor that allows the contents of the flask to be heated.

At high temperatures, solvent and other reactants interchange between gas and liquid state. This contributes to the increased pressure in the system. Low temperature and pressure reactions can also be conducted.

Rotary evaporator

Room: 1041

Responsible person: Lauren Ball

A rotary evaporator (Rotavap) is used for the gentle removal of solvents from samples via evaporation. A rotary evaporator lowers the boiling point of a solvent by reducing the pressure above the liquid, thus evaporating the solvent efficiently. This allows liquid solvents to be removed without excessive heating of the sample.

Rotary evaporation is most often and conveniently applied to separate low-boiling solvents such as n-hexane or ethyl acetate from compounds which are solid at room temperature and pressure. However, careful application also allows removal of a solvent from a sample containing a liquid compound.

Centrifuge

Room: 1037

Responsible person: Lauren Ball

The centrifuge spins liquid samples at high speeds using a rotating arm in a cavity. The centrifuge works on the sedimentation principle, where the centripetal acceleration seperates substances based on their density eg. colloidal particles suspended in a liquid. The instrument has a maximum rotor speed of 5000 rpm.

VirTis BenchTop freeze dryer

Room: 1016

Responsible person: Lauren Ball

Freeze drying allows the removal of a solvent (usually water) from dissolved or dispersed solids. The frozen product is connected to the freeze drying instrument which is under vacuum, creating a near vacuum environment. Moisture is extracted through sublimation while maintaining the material’s crystalline structure. The freeze drying process is particularly suitable for products which are sensitive to heat, subject to oxidation, or shear sensitive.

Benchtop injection moulder

Room: 1007

Responsible person:

Haake Minijet®. This instrument allows for injection moulding of samples with as little as 800 mg of material (disk, dumbbell and impact strip moulds). This enhances our capability to do physical tests on fractionated materials, as prep-TREF fractionation occurs on a maximum of 3 g of material. Similarly, some synthesis experiments will yield small amounts of material.

These moulds can be used for tensile tests, three-point bending tests, microhardness evaluation, even positron annihilation spectroscopy and as sample source for TEM and SEM experiments.

Microtome

Room: 1007

Responsible person:

The RM2245 is a semi-motorized rotary microtome with a light-action handwheel. The RM2245 supports two manual sectioning modes: rocking mode and conventional sectioning with full turns of the handwheel. The instrument features two independent handwheel locking systems for enhanced user safety. It also features an adjustable retraction system. The retraction value can be selected as required. The motorized specimen head can be moved at two speeds. The minimum and maximum specimen head end positions are signalled visually and acoustically. The thickness for trim and sectioning modes can be programmed and stored independently. Manual sectioning is enhanced by a high-precision motorized specimen feed, which results in efficient operation with maximum section quality and reproducibility.

Brabender

Single and twin screw extruder with twin roll mill

Room: 1020

Responsible person: Prof AJ van Reenen