Contact us

Division of Polymer Science

Department of Chemistry

and Polymer Science

University of Stellenbosch

Private Bag X1

7602 MATIELAND

South Africa

Telephone:

+27 (21) 808 3172

Where to find us

GPS Coordinates:

S 33° 55' 58" E 18° 51' 59"

Equipment available at Polymer Science

Last revision: 13 November, 2020

Other equipment

DDI water Ultra Turrax IKA T25 Picoclave reactor Rotary evaporator Centrifuge VirTis BenchTop freeze dryer Benchtop injection moulder Microtome Brabender

Distilled-deionised water

Room: 1037

Responsible person: Lauren Ball

The PureLab produces type II, distilled-deionised water, perfect for a wide range of applications such as reagent make-up, buffer preparation and general purpose HPLC. It delivers seven litres of water an hour with high purity (15 MΩ-cm). Constant water recirculation maintains consistent water purity. The instrument comprises a pre-treatment cartridge, reverse osmosis cartridge, ion-exchange module and a photo-oxidation module to remove bacteria.

Room: 1037

Responsible person: Lauren Ball

Dispersions are mixtures of at least two substances that: don’t dissolve in each other, marginally dissolve in each other, or don’t chemically react with each other. During a dispersing process one substance (dispersed phase) is distributed throughout another substance (continuous phase). The term coined for such a mixture is an emulsion or suspension.

Dispersion with an ULTRA TURRAX is based on the rotor-stator principle. In this process the rotor is moved with high circumferential speed. The rotation produces suction that pulls the medium into the rotor and then pushes it to the outside with the help from the stator’s teeth. The products are either emulsions (liquid droplets in a continuous phase) or dispersions (solid particles smoothly distributed throughout the continuous phase). Dispersing with an ULTRA TURRAX is considered to be a high shear process for the dispersion of liquid droplets and solid particles in a continuous phase. This process is a simple and effective alternative to sonication to achieve emulsions and dispersions in a relatively short time scale compared to sonication.

Room: 1037

Responsible person: Lauren Ball

The reactor allows reactions to be conducted at high temperatures (~180°C) and pressure (8 bar < x < 10 bar) while applying a high degree of agitation (3000 rpm). It features an oil bath with temperature control and a double walled glass reactor that allows the contents of the flask to be heated.

At high temperatures, solvent and other reactants interchange between gas and liquid state. This contributes to the increased pressure in the system. Low temperature and pressure reactions can also be conducted.

Room: 1041

Responsible person: Lauren Ball

A rotary evaporator (Rotavap) is used for the gentle removal of solvents from samples via evaporation. A rotary evaporator lowers the boiling point of a solvent by reducing the pressure above the liquid, thus evaporating the solvent efficiently. This allows liquid solvents to be removed without excessive heating of the sample.

Rotary evaporation is most often and conveniently applied to separate low-boiling solvents such as n-hexane or ethyl acetate from compounds which are solid at room temperature and pressure. However, careful application also allows removal of a solvent from a sample containing a liquid compound.

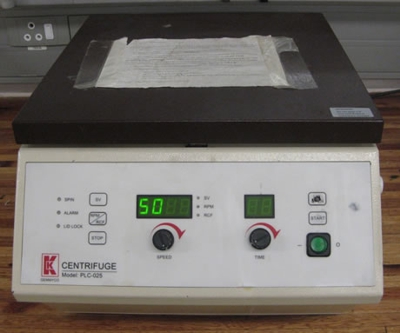

Room: 1037

Responsible person: Lauren Ball

The centrifuge spins liquid samples at high speeds using a rotating arm in a cavity. The centrifuge works on the sedimentation principle, where the centripetal acceleration seperates substances based on their density eg. colloidal particles suspended in a liquid. The instrument has a maximum rotor speed of 5000 rpm.

Room: 1016

Responsible person: Lauren Ball

Freeze drying allows the removal of a solvent (usually water) from dissolved or dispersed solids. The frozen product is connected to the freeze drying instrument which is under vacuum, creating a near vacuum environment. Moisture is extracted through sublimation while maintaining the material’s crystalline structure. The freeze drying process is particularly suitable for products which are sensitive to heat, subject to oxidation, or shear sensitive.

Room: 1007

Responsible person: Janus Barnard

Haake Minijet®. This instrument allows for injection moulding of samples with as little as 800 mg of material (disk, dumbbell and impact strip moulds). This enhances our capability to do physical tests on fractionated materials, as prep-TREF fractionation occurs on a maximum of 3 g of material. Similarly, some synthesis experiments will yield small amounts of material.

These moulds can be used for tensile tests, three-point bending tests, microhardness evaluation, even positron annihilation spectroscopy and as sample source for TEM and SEM experiments.

Room: 1007

Responsible person: Janus Barnard

The RM2245 is a semi-motorized rotary microtome with a light-action handwheel. The RM2245 supports two manual sectioning modes: rocking mode and conventional sectioning with full turns of the handwheel. The instrument features two independent handwheel locking systems for enhanced user safety. It also features an adjustable retraction system. The retraction value can be selected as required. The motorized specimen head can be moved at two speeds. The minimum and maximum specimen head end positions are signalled visually and acoustically. The thickness for trim and sectioning modes can be programmed and stored independently. Manual sectioning is enhanced by a high-precision motorized specimen feed, which results in efficient operation with maximum section quality and reproducibility.

Single and twin screw extruder with twin roll mill

Room: 1020

Responsible person: Prof AJ van Reenen